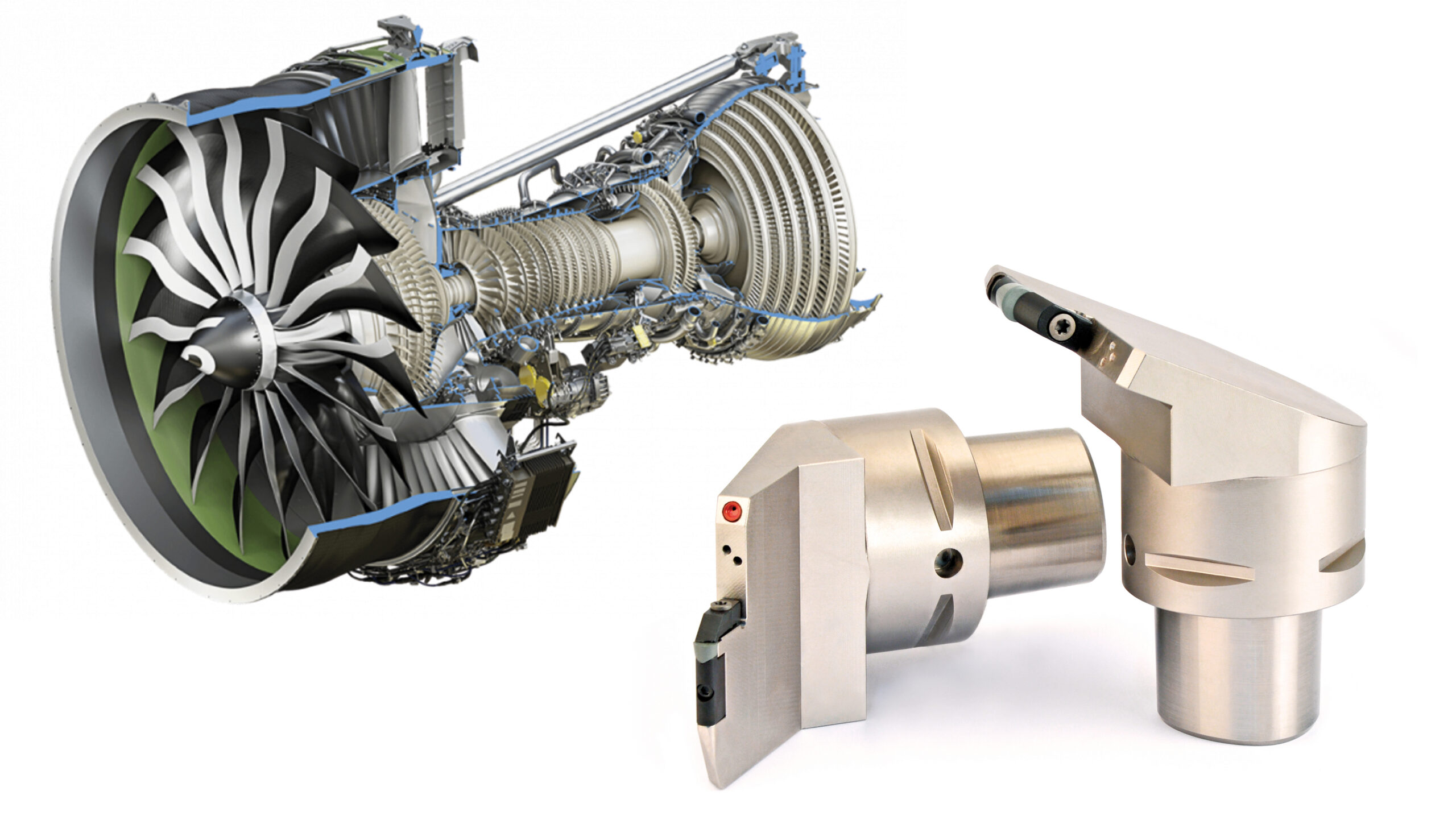

Aerospace

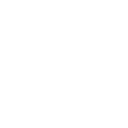

Aerospace industry materials and production technology are changing rapidly and continuously. The use of difficult-to-cut materials such as titanium and carbon fibre reinforced plastic has increased due to the weight reduction demands of the industry, along with aluminium alloys.

Canela works closely with customers to deliver tools that meet stringent requirements and high safety standards, achieving much higher speeds and feed rates, along with increases in the available power, in order to achieve consistent results and a longer tool life.

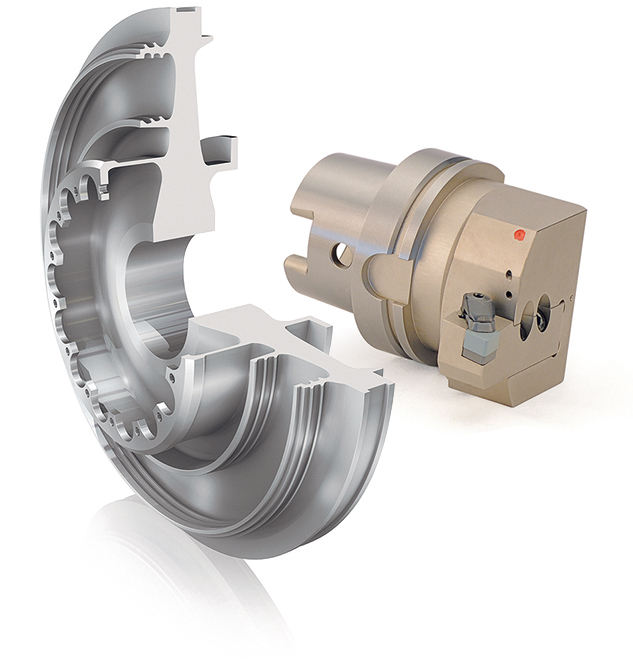

In aerospace machining, companies need to deliver parts with high precision, accuracy and speed. Each component of an airplane must have the correct dimensions and at the same time contribute to reduce the aircraft’s weight and meet the latest standards for durability and safety.

Canela has developed solutions to address the growing demand for improved machining solutions for aerospace parts. These solutions provide our customers with tremendous competitive advantages to produce high-quality parts with high accuracy, reduced cycle times, and optimum cost per part. Our long-standing experience in providing competitive machining solutions for aerospace machining, together with our innovative capabilities and desire to improve our solutions continually, are all reasons this is possible. Learn how Canela provide you with both time and resource savings when machining aerospace parts.

In aerospace machining, lightweight resistant material are used. Lightweight material reduces the weight of the aircraft, improves the fuel economy and maintains safety. Both aluminum and titanium are used for those parts.

- SiAION.

- Eliminate Traditional Ceramics Limitations.

- Depth-of-cut notching is no longer a limitation for SiAlON ceramics. When notching is severe, primarily with roughing cuts, tougher ceramic grades are applied.

- Specials.

From the hand sketch to the precision product! As a tool supplier and developer, we address the special tool requirements of our aerospace customers and construct them as custom-made products according to customer specifications and our know-how.